EMO Hannover 2023 World Tour is proceeding as scheduled. So far, the World Tour, both digital and live on site, has been held in Canada, the United States, Indonesia, South Africa, Greece, Romania, South Korea, Japan, Thailand, India and China, spreading over five continents around the world. Hannover is calling for experts from around the globe, after four-year absence, to come and enjoy the world of metalworking at EMO exhibition.

Since May 2022, the organizer has been hosting a webinar on the last Wednesday of every month at 11:30am (CET), inviting renowned scientists from the metalworking industry to discuss the future of production technology, allowing us to get a taste of what’s coming up in the industry before EMO Hannover even gets under way.

The topics of the webinars are abundant,and it is impossible for us to go over them one by one. So here we only take the latest seminar topics as an example, which will give us a glimpse of what is going on.

The current topic is: Hybrid manufacturing saves up to 50 % time and 80 % material.

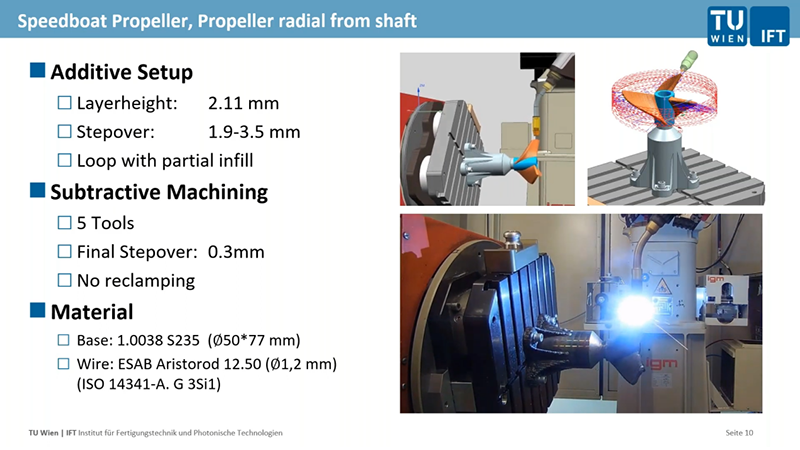

In past years, additive technologies have gained more interest in academia and industrial applications. Especially technologies such as “Direct Energy Deposition (DED)” and “Wire-Arc Additive Manufacturing (WAAM)” are frequently used for various industrial scenarios such as repair processes or multi-material applications.

While the potentials of additive technologies have been demonstrated in recent years, still several “trial and error” experiments are necessary in order to achieve stable manufacturing process conditions and to fulfill part quality requirements. Especially the complexity of multi-material additive manufacturing is much higher compared to single material-based AM due to various factors. These include the compatibility of different materials, identification of appropriate processes, finding process parameters that work well with different materials, and reducing material-specific and associated consumables.

These and other research results support the vision of automated process planning steps for additive process chains, making the usage of such technologies more efficient and provide industrial companies with an earlier return on investment. The new methods not only save time, but also up to 80% material, depending on the component geometry.

List of Past Webinar Topics:

Hybrid manufacturing saves up to 50 % time and 80 % material

29/03/2023 – 13:30-14:30

Manufacturing will no longer be planned by humans

22/02/2023 – 12:30-13:30

Innovative machining method significantly reduces production costs

25/01/2023 – 12:30-13:15

Wireless production thanks to 5G mobile communications standard

31/08/2022 – 10:30-11:15

AI is finally becoming widely usable

29/06/2022 – 10:30-11:15

Matrix production – new possibilities for the integration of technologies

27/07/2022 – 10:30-11:15

How SMEs become sovereign data holders

28/09/2022 – 10:30-11:15

Guide: Implementing AI models sustainably

30/11/2022 – 09:30-10:15

Classic sheet metal forming becomes more economical and ecological

26/10/2022 – 10:30-11:15

Rethinking products thanks to 3-dimensional electronics

25/05/2022 – 10:30-11:15

Open Source Machine Tools: The road to Production Sovereignty and Circular Economy

Coming next:

31/05/2023 – 11:30-12:30

How do you use data for new business models?

Every webinar has recordings. If you are interested in any of the monthly live webinars, feel free to contact us or go to EMO Hannover website.

Copyright ©2008-2023 Xi'an Eurasia Machinery Equipment Co.,Ltd All Rights Reserved

网站备案号:陕ICP备20002798号-1

Copyright ©2008-2023 Xi'an Eurasia Machinery Equipment Co.,Ltd All Rights Reserved

网站备案号:

陕ICP备20002798号-1